Jan 26, 2026

Joining Forces to Shape a New Intelligent Manufacturing Ecosystem: Kardex and Heli Yufeng Enter Strategic Partnership

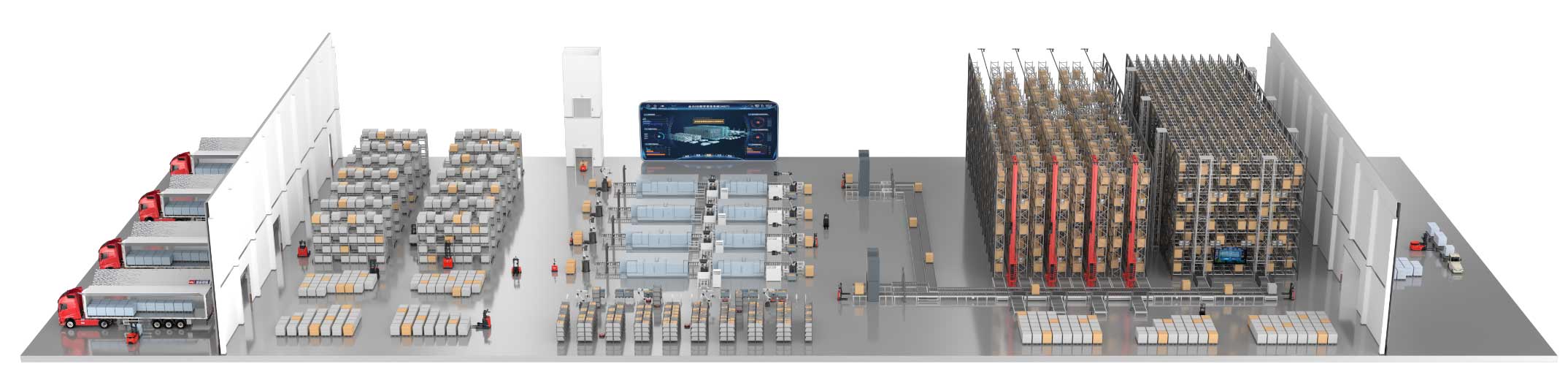

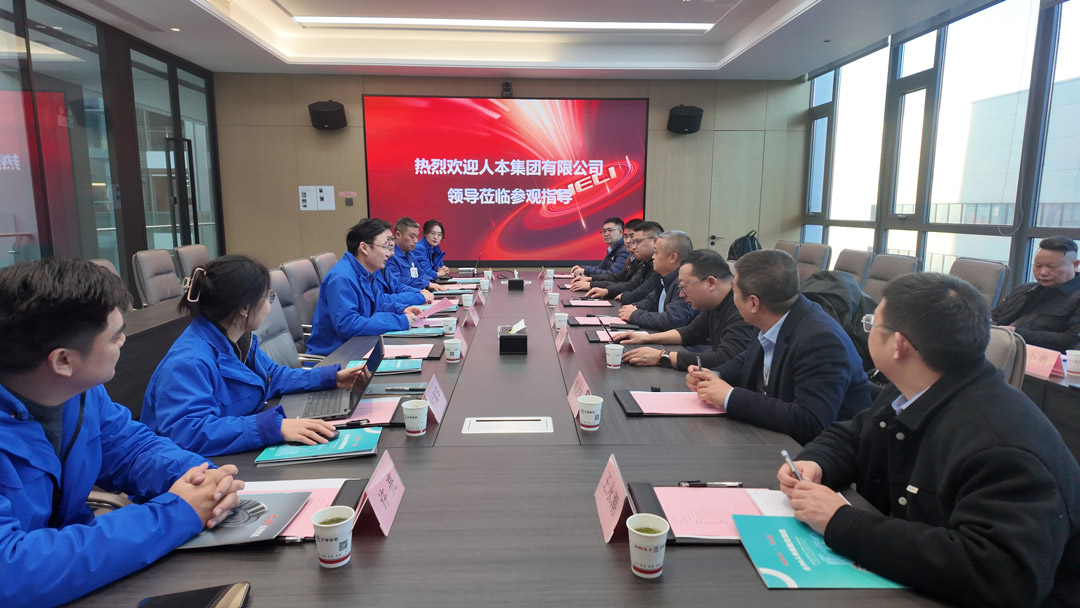

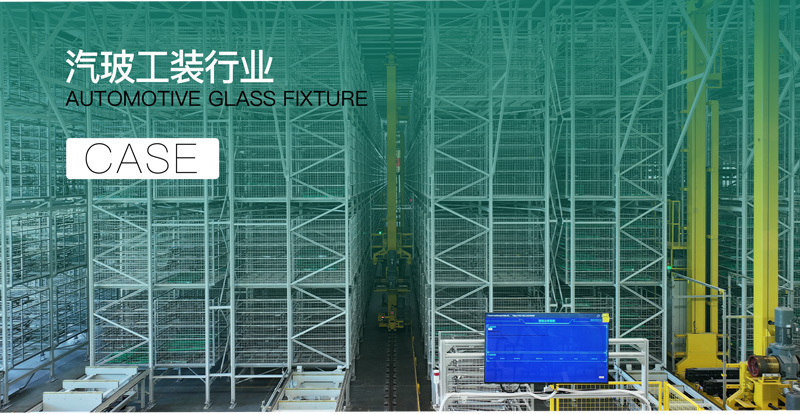

December 15, 2025 — Kardex, a global leader in intralogistics automation, and Anhui Heli Yufeng Intelligent Technology Co., Ltd. (Heli Yufeng), a national “Sci-Tech Reform Demonstration” enterprise, officially signed a strategic cooperation agreement at Kardex’s Shanghai headquarters. The two parties will establish a joint brand, marking a new chapter in the deep integration of German and Chinese technologies in intelligent logistics. A Century of German Engineering × A Pioneer of China’s Intelligent Manufacturing Founded in 1873, Kardex has continuously set industry benchmarks. Since launching the world’s first automated storage system in 1957, Kardex has delivered over 200,000 systems worldwide, serving customers in more than 30 countries and holding a leading position in automated high-density storage. Heli Yufeng, a holding subsidiary of Anhui Heli Co., Ltd., has been recognized as a National High-Tech Enterprise, a national “Little Giant” specializing in niche technologies, and a recommended brand in China’s intelligent logistics sector. Centered on four core businesses—intelligent warehousing, intelligent handling, intelligent factories, and intelligent parks—Heli Yufeng leverages nearly 70 years of Heli Group’s technical expertise to build a comprehensive portfolio covering logistics robots, AMRs, intelligent integration systems, and digital twin platforms. The company has delivered benchmark projects across industries including new energy, chemicals, food & cold chain, automotive, metallurgy, and semiconductors. Complementary Technologies for End-to-End Solutions This partnership focuses on deep synergy. Kardex will contribute its proven vertical lift modules and carousel storage systems, while working with Heli Yufeng and Heli Group’s global network of over 1,000 sales and service organizations. Together, they will provide customers with full-lifecycle, one-stop intelligent logistics solutions—covering consulting, planning, product development, implementation, delivery, and after-sales service. Industry Synergy, Expanding Key Markets Kardex brings strong expertise in machinery manufacturing, semiconductors, aerospace, and healthcare, while Heli Yufeng has deep roots in new energy, chemicals, food cold chain, and automotive parts. By integrating industry know-how and channel resources, the two companies will jointly advance benchmark projects in high-end manufacturing, semiconductors, cold chain logistics, and new energy sectors. Executive Perspectives Jeffrey Cha, Head of Kardex China, commented: “Heli Yufeng’s strong localization capabilities and industry reach will help us deliver our world-leading technologies to Chinese customers more efficiently.” Li Daoliang, Party Secretary, Chairman, and General Manager of Heli Yufeng, added: “Kardex’s global technology vision and product reliability will significantly enhance the competitiveness of our joint solutions.” Moving Forward Together As China’s manufacturing sector accelerates its ...

Baca lebih lanjut

Gudang automatik

Gudang automatik